Lately I’ve found myself advocating for higher priced brands quite often, and one of the most common things I hear from consumers in response are things like ‘Damn, those guys must not care about their end users!’ Or ‘where do they get off charging so much for a 3.5 grams of flower?’ When Dante did his piece for WEIRDOS a few weeks back it had a similar reaction. While I do understand the sentiment, I’d like to set the record straight a bit, because I assure you, if they didn’t care about providing you with the best possible products they can, they simply wouldn’t be in this business.

You see, the reason you hear so much about brands trying to go ‘vertical’, or racing to scale, is because as it turns out, there’s not a ton of money in selling weed anymore. In order to optimize profits, and frankly make the business worthwhile, brands need to move a LOT of work, as this really isn’t a high margin business in the legal landscape. In fact, there are a million hurdles even the smallest of brands have to overcome to get their product to market. They are burdened with hard costs, a complicated legal system, and in truth, the initial cultivators often have the smallest say in terms of end price. They’re just trying to stay afloat.

My dear friend Drew Coggio, proprietor of Green Dawg Cultivators, said poetically of the state of the industry right now:

“Overall, the operators starve while the city eats. The state reaps while farmers weep.”

This couldn’t be more accurate, and I’d like to illustrate the reality of the game today.

Reverse Engineering The Price

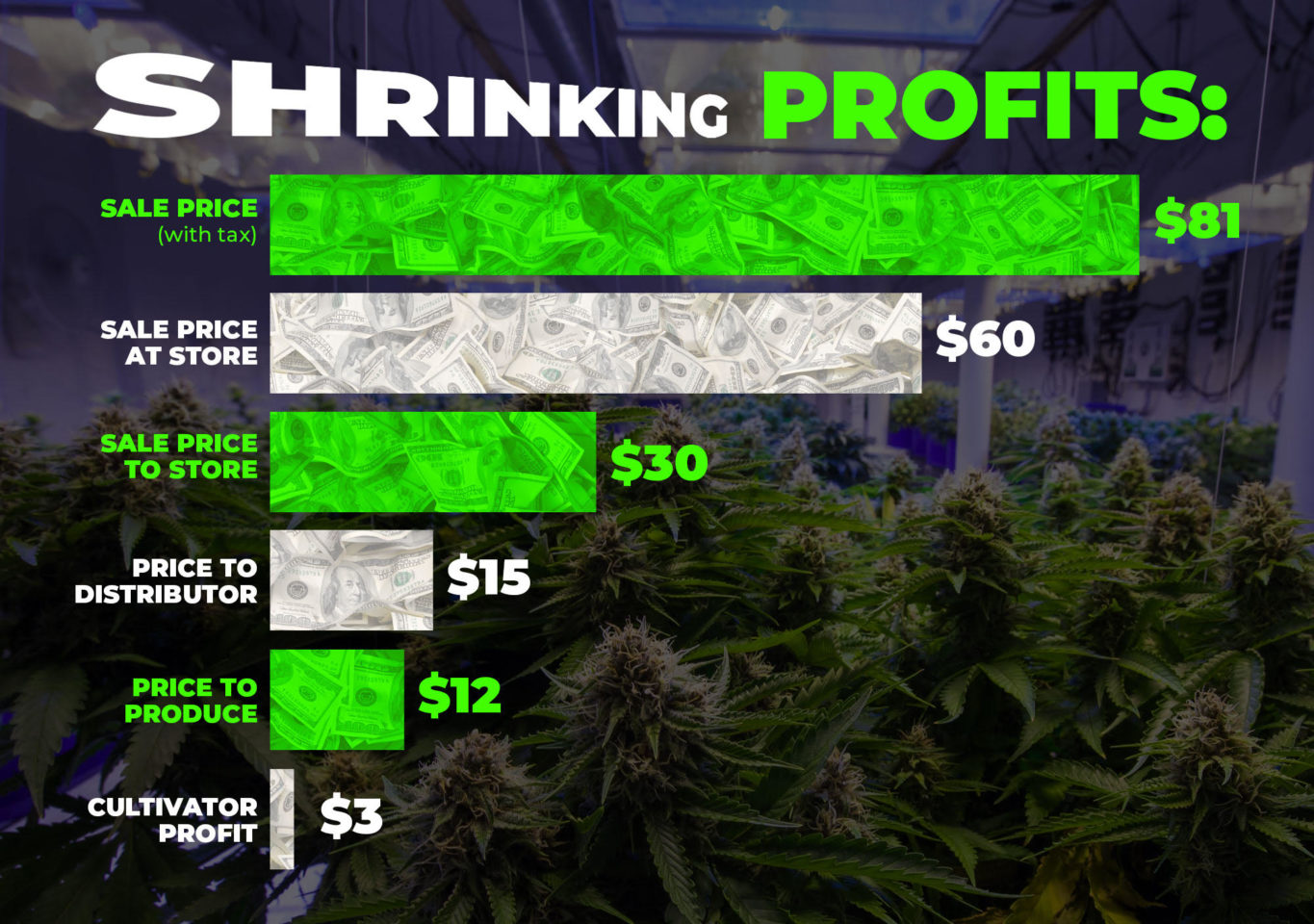

Let’s journey down the path of a top shelf eighth (and we’ll say it’s been sold at a fairly priced store – none of that hype shop noise – to keep numbers consistent) of a company that’s not fully vertical. To the end consumer in Los Angeles, when starting at $60 on the shelf, this equates to about $81 out of pocket when all is said and done. Sounds like a ton of money, right? The farmers must be making a killing! Well hold on now, not so fast.

That eighth had to be sold to a retailer, so as we travel backwards down the path, let’s see how that $60 shrinks. Because remember, that extra $21 is tax. None of the operators eat off that, that’s the states money.

The retailer probably bought it around $30, as retailers typically mark products up about 100% (on the fair side). So we’re at $30 to the farmer, right? But what about the distribution company? They might have bought it for $15/per, and marked it up, because they also need to make money, and provide a living wage to their employees. So now we’re at $15 per eighth, for a product that’s sold to the consumer for $60 – margins are shrinking fast, but still, $15 for 3.5 grams, surely that’s a killing for the farmer. Right? Not when you factor in expenses, my dear!

Production Costs

Before we get into the costs of actually creating a viable grow room, there are a lot of hard costs in cultivation. Things like electricity, and water, are essential to the indoor grow process, and while these prices vary by where in the state you’re operating, I’ve spoke to a few friends in the process of writing this to generalize the costs.

Depending on the yields of your plants, an eighth can cost between $9-12 to grow indoors at the highest quality. Now, that price scales to the more expensive end as you factor in things like exotics are typically lower yielders, and that some plants take longer to finish.

But remember, the cultivator is also being taxed here. The state will come in and take about 5% of gross sales from the cultivator on top of all the taxes the end consumer is paying. They have also been paying a ~$170/lb tax that was just recently lifted by California since so many cultivators have been going under, but it’s important to note that this extremely recent change has yet to be felt by the cultivators.

Then they’ve also got to package your products. Because ziplocks are no good anymore, the state requires all that child safe stuff, and it’s gotta happen before it hits the store. So besides all of the cultivation costs, there’s another dollar or two tacked on in hard costs just to brand the goods and get them to you. That means if the cultivator WAS seeing $15/eighth, after hard costs they’re only seeing around $1-5 per eighth in profit.

Hardly anything to write home about, and we haven’t even gotten into what it takes to get to this point!

Pre Production Costs

We all know that top shelf indoor doesn’t grow in a dump, right? There’s a LOT that goes into setting up a room, and while it’s hard to deduct these costs from an individual eighth, I feel it’s important to give you some context into just how expensive setting up one of these rooms is, and how much it takes to run it.

Build outs cost between $300-500 PER SQUARE FOOT of facility you’re operating in. That means if you’re setting up a 1,000 sq ft facility you’re looking at $300-500k, or at 10,000 sq ft $3-5 million.

Past that, those expenses I mentioned have monthly costs. Operating the facility can cost between $5-8 per sq foot per month. That can translate to $5-8k per month at a 1,000 sq ft facility, or $50-80k per month at the 10,000 size. As you can see, these numbers are adding up QUICK.

And we haven’t even added in the costs to actually become a legal operator, and not just a traditional one. That probably takes another million or so as it’s such an annoying and complicated process that I’m not even going to get into it.

So with hundreds of thousands in set up costs, tens of thousands in operational per month, and around $3 profit per eighth, remind me again about how greedy these guys are? The cultivators, not the state. Those guys are caking up.

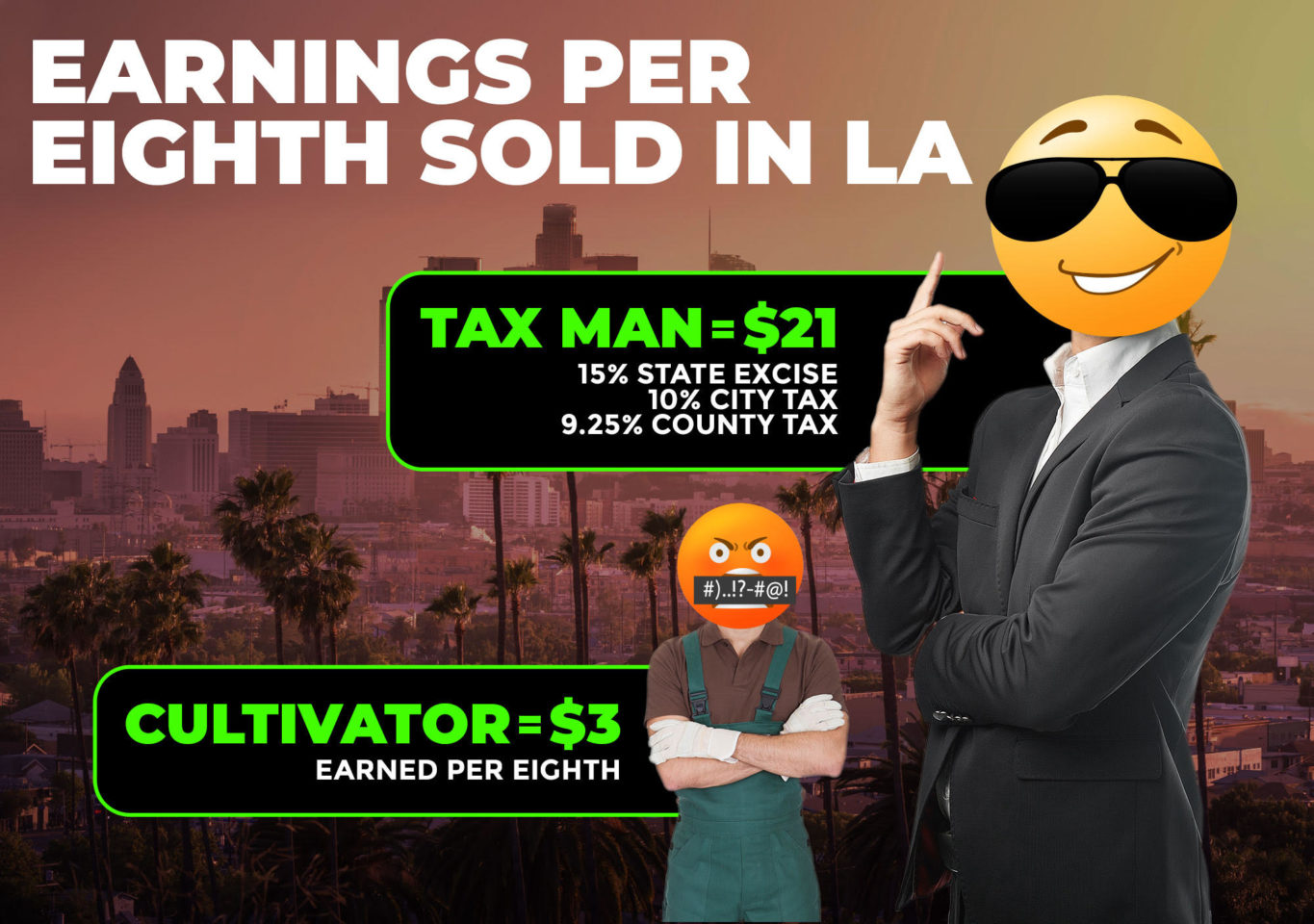

The Man

The sad truth is the one who’s fucking us here isn’t the cultivator, it’s the government. Their crazy taxes and restrictions are the reason why most of this process is so expensive, and why hardly anyone is making a great check right now. To break them down quickly, and using Los Angeles as an example, 34.5% of whatever the final cost of your goods are went directly to the government in this county. That means over 1/3 of what you’re paying doesn’t feed or support any of the people actually involved in the making of your product – just the legislators making this process so difficult for them.

That 34.5% breaks down as follows: 15% State Excise Tax, 10% City Tax, 9.25% County tax. All to the man for giving you the privilege to spend this much money on weed.

Even worse, U.S. Tax Code 280E says that everyone involved in the sale of federally illegal *drugs* are taxed at the highest rate possible, which means that 43-47% of anything those involved in the process makes goes right back to the feds. They are literally doing everything they can to make sure these guys DON’T make money.

I haven’t even gotten into the mechanics of retailers and distributors, who while I understand may also seem greedy off the rip because of their mark ups, are actually mostly barely surviving as well. It’s easy to forget how hard it is to run a business, to feed your staff, and pay all your bills – in any industry. But I assure you, the game is further rigged in cannabis – and that’s why everyone’s so excited to sell merch!

Support your people

When all’s said and done, I understand why consumers are pissed about prices. The state of the industry today sucks, truly. But it’s not the fault of those of us who are cultivating, it’s largely due to the states greed. While we all want a better tomorrow, let’s do our best to help those who ARE focused on providing us with the best products possible, and not just those with the money to race to scale to make MORE money off us. I understand that quantity looks appetizing, but trust me, quality will get you there way faster, every time.

The post Where Does The Money Go? appeared first on High Times.

Source: https://cannabisworld.biz/2022/07/29/where-does-the-money-go/